Adding hops to beer either during or after fermentation has been done for centuries, but an unexpected side effect has recently arisen. Some newly created beer styles with extremely high hopping levels are refermenting beer in what is called dry hop creep.

Table of Contents

Boiled Down Summary

- Dry hopping is the addition of hops during or after fermentation to add hop aroma to beer.

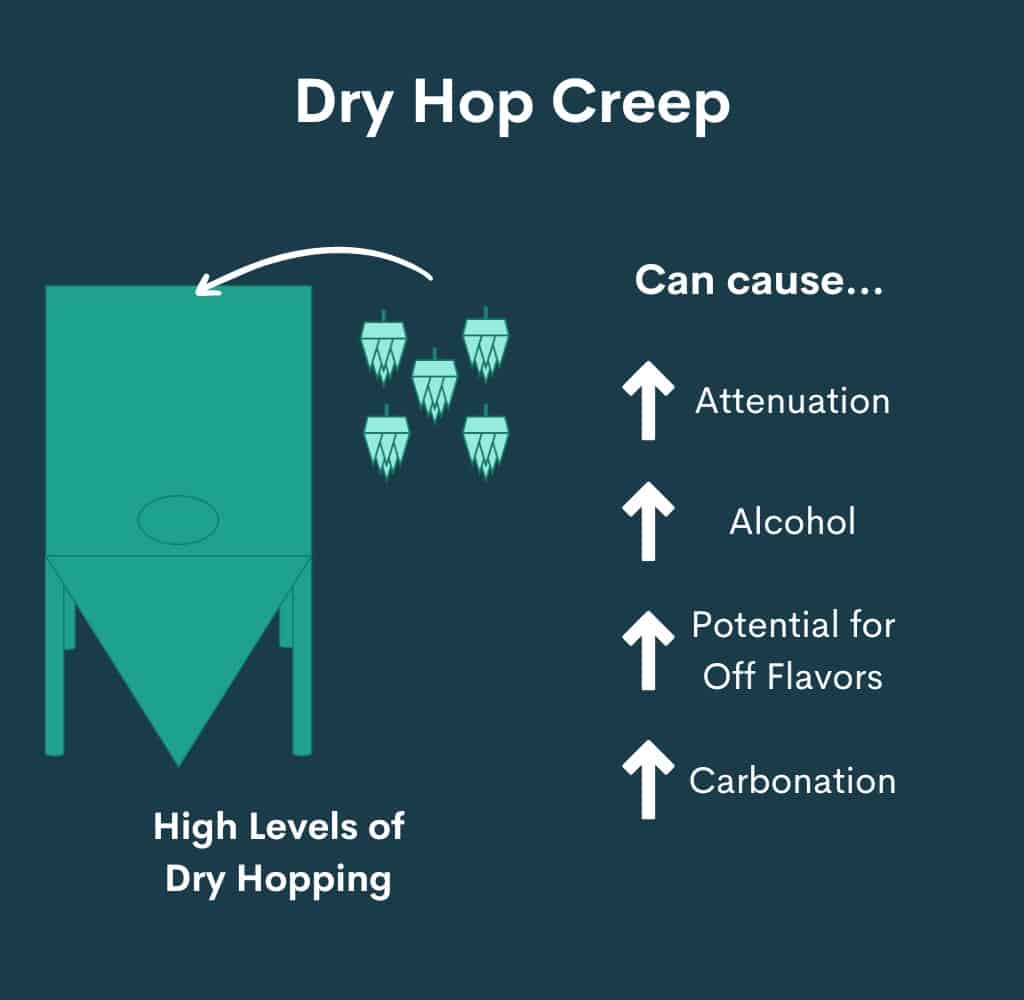

- Dry hop creep is a phenomenon where dry hop additions lead to higher-than-expected levels of attenuation in beer.

- The higher attenuation is caused by refermentation and is likely due to enzymes in hops that can convert dextrins to fermentable sugars.

- There are some suggested techniques to mitigate dry hop creep, including pasteurizing the beer, controlling dry hopping conditions, and kilning hops at a higher temperature.

What is dry hopping?

Traditionally, hops are added on the hot side of the brewing process to impart bitterness through iso-𝛼-acids formation and hop aroma through additions late in the boil, where hop essential oils are preserved. However, brewers can also add hops either during or after fermentation to increase hop aroma in a beer with a minor impact on bitterness. This process is called dry hopping.

Of the classic beer styles, English pale ales are best known for being dry hopped, where hops were added to casks before filling from the 1800s onward to impart hop aroma (Oliver, 2012, pp.307-309). Some of today’s modern beer styles, mainly US ales like American IPA and Hazy IPA, have taken this practice to a much higher level, with hopping rates exceeding 10 grams of hops per liter of beer.

With this increase in dry hopping, brewers have found that adding enormous amounts of hops can suddenly cause refermentation of the beer, a phenomenon called hop creep.

Dry hop creep overview

Dry hop creep is when dry hop addition leads to a higher level of attenuation in beer than expected. The increase in attenuation is generally thought to be caused by endogenous enzymes in hops capable of hydrolyzing dextrins to fermentable sugars that can be refermented by the yeast in the beer (Bruner et al., 2020).

However, as dry hop creep is a relatively new topic in beer, there is still limited understanding of all the factors that affect this phenomenon. Recent research has examined the impact of hop variety, yeast strain, and microbes introduced to the beer through dry hop addition, as well as other factors that may impact hop creep, all of which are explored in a later section of this article.

In addition to over-attenuation of the beer, refermentation from dry hop addition also creates other potential issues for brewers. For example, refermentation can cause an increase in alcohol content, carbonation level, and the level of off-flavors like diacetyl and acetaldehyde (Cottrell, 2022).

Recent research on dry hop creep

With an increased focus from US craft brewers on highly dry-hopped beer styles, there has also been an increase in research on dry hop creep. Recent studies have examined the impact that hop variety, yeast strain, and microbes on hop products have on dry hop creep.

A study by Bruner et al. (2020) tested the ability of various American hop varieties to referment a commercial lager and a commercial ale by adding 10 g/L of hops and fresh yeast to the beers. The group followed the alcohol content in the beers over 30 days, comparing the results to control beers with no addition, with only yeast addition, and with only hop addition.

The research group found that, on average, the lager increased in alcohol content by 1.04% v/v and the ale by 0.82% v/v with hop and yeast addition, compared to no significant increase for the hops alone, and 0.20% v/v and 0.38% v/v alcohol increase for just the yeast addition for the lager and ale, respectively. The study tested Amarillo, Centennial, Mosaic, and Willamette hops and found no statistical difference in alcohol increase between hop varieties.

A study by Cottrell (2022) investigated the microbes on hop pellets and their potential contribution to hop creep. The study isolated bacteria and fungi from Azacca, Cascade, Centennial, Citra, Galaxy, and Mosaic hop pellets. Of the 68 microbes isolated, 9 could degrade starch based on iodine clearing ability on starch-based media.

To test the ability of the starch-degrading microbes isolated in this study to continue attenuation of finished beer, one bacterial and one fungal strain from the study were added to separate samples of packaged Pale Ale and incubated for two months, then examined for apparent extract and alcohol content changes. For comparison, another sample of Pale Ale was dry-hopped with Citra hops and stored for 48 days, along with a control with no additions.

The study found that while the isolated microbes could produce amylase, they did not decrease apparent extract or increase the alcohol content of the beer. This was in contrast to a 25% reduction in apparent extract and a 7% increase in alcohol content for the dry-hopped beer.

Mitigation of dry hop creep

Though it’s a new phenomenon, various publications and conference proceedings do offer insights into how dry hop creep may be managed.

In a 2020 Craft Brewers Conference presentation titled Hop Creep: What It Is and Approaches to Managing It, brewers, quality control professionals, and researchers presented various insights into dry hop creep. Tom Shellhammer of Oregon State presented data which demonstrated that longer time, high temperature, and higher hopping rates in dry hopping could lead to higher levels of sugar production (Cilurzo et al., 2020).

In a poster at the World Brewing Congress Connect 2020 titled Controlling the Creep: Potential Cellar Interventions to Mitigate Dry-Hop Creep, Stokholm & Shellhammer (2020) presented work testing various cellaring techniques to control dry hop creep. They tested protease enzyme addition, pH adjustment of the beer at the beginning of dry hopping, and pasteurization of the beer. They found that only pasteurization effectively decreased the amount of sugar released after 10 g/L dry hop addition under their tested conditions.

On the hop production side, Lafontaine et al. (2019) demonstrated in a poster titled Impact of kiln temperatures on the enzymatic potential of hops that kiln temperature when drying hops may have an impact on the diastatic potential of hops. The group demonstrated that higher kiln temperatures significantly reduced the diastatic power of hops in Amarillo and Simcoe hops from Washington and Idaho.

In the previously mentioned Cottrell (2022) study that examined potential microbial contribution to hop creep, Cottrell also identified a genetic basis for amylase production in hops. Cottrell suggested that with the rise of CRISPR technology it might be possible to produce hops that are amylase-free if it is determined that the encoded amylases are not essential for hop growth.

References

Bruner, J., Marcus, A., & Fox, G. (2021). Dry-Hop Creep Potential of Various Saccharomyces Yeast Species and Strains. Fermentation, 7(2). https://doi.org/10.3390/fermentation7020066

Bruner, J., Marcus, A., & Fox, G. (2022). hanges in Diacetyl and Amino Acid Concentration during the Fermentation of Dry-Hopped Beer: A Look at Twelve Saccharomyces Species and Strains. Journal of the American Society of Brewing Chemists. https://doi.org/10.1080/03610470.2022.2078946

Bruner, J., Williams, J., & Fox, G. (2020). Further Exploration of Hop Creep Variability with Humulus lupulus Cultivars and Proposed Method for Determination of Secondary Fermentation. MBAA Technical Quarterly, 57(3), 169-176. https://doi.org/10.1094/TQ-57-3-1002-01

Cilurzo, V., Vaughan, C., Beauchamp, A., Kravitz, M., & Shellhammer, T. (2020). Hop Creep: What It Is and Approaches To Managing It [Craft Brewers Conference Online 2020]. https://www.brewersassociation.org/wp-content/uploads/2020/05/CBC-Online-Seminar-Presentation-Hop-Creep-What-It-Is-and-Approaches-to-Managing-It.pdf

Cottrell, M. T. (2022). A Search for Diastatic Enzymes Endogenous to Humulus lupulus and Produced by Microbes Associated with Pellet Hops Driving “Hop Creep” of Dry Hopped Beer. Journal of the American Society of Brewing Chemists. https://doi.org/10.1080/03610470.2022.2084327

Lafontaine, S. R., Rubottom, L. N., Hauser, D. G., & Shellhammer, T. H. (2019, June 24). Impact of kiln temperatures on the enzymatic potential of hops [ASBC Meeting 2019]. https://www.researchgate.net/publication/336746482_Impact_of_kiln_temperatures_on_the_enzymatic_potential_of_hops

Oliver, G. (2012). The Oxford Companion to Beer. Oxford University Press.

Stokholm, A., & Shellhammer, T. H. (2020, October 8). Controlling the Creep: Potential Cellar Interventions to Mitigate Dry Hop Creep [WBC Connect 2020]. https://www.researchgate.net/publication/347469265_Controlling_the_Creep_Potential_CellaC_Interventions_to_Mitigate_Dry-Hop_Creep